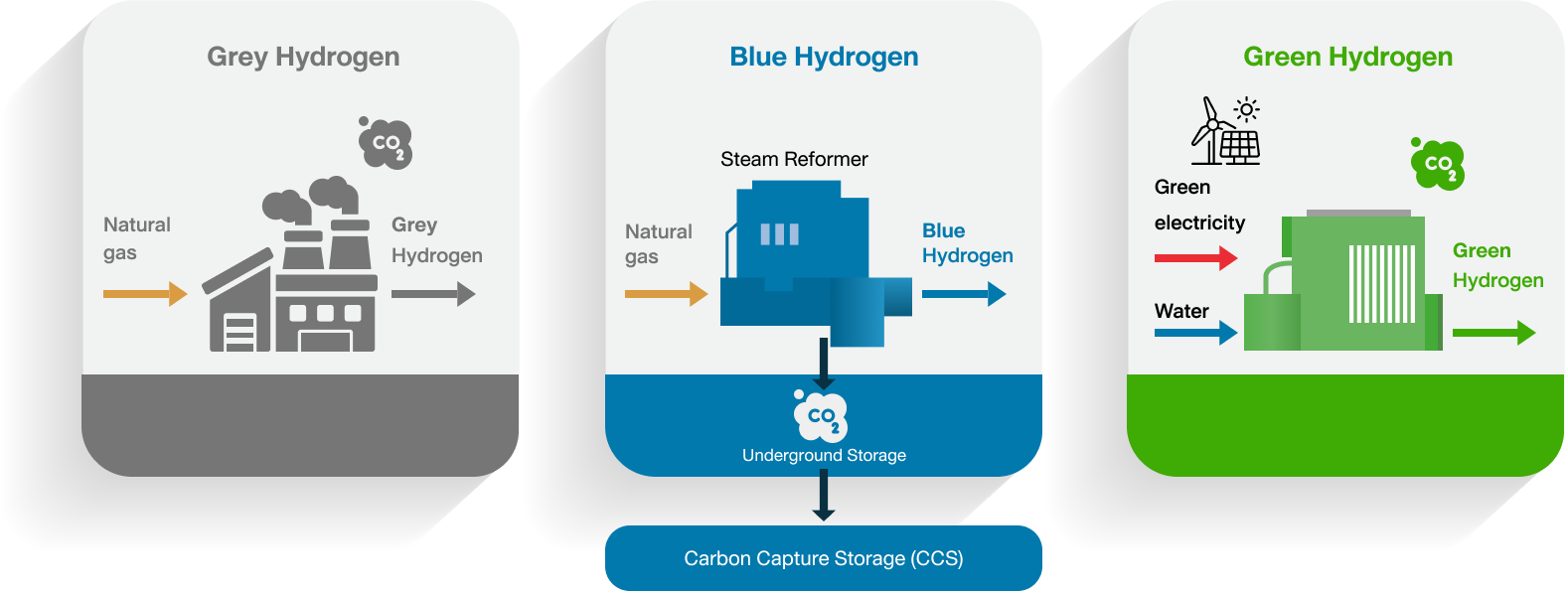

Alternative Energy refers to energy sources that are not derived from traditional fossil fuels, which generate hydrocarbon compounds and release carbon dioxide (CO₂) into the atmosphere. According to the International Energy Agency (IEA), hydrogen plays a crucial role in reducing CO₂ emissions. Embracing clean energy-derived hydrogen is pivotal in driving the petrochemical industry towards sustainability.

The Walfire Radiant Wall Burner is an advanced combustion system specifically designed for industrial plants. It can use up to 100% hydrogen as fuel without the risk of flashback. This innovative burner is engineered to ensure ultra-low NOx emissions, utilizing cutting-edge INFURNOx™ technology.

The burner's flame design is customizable, offering flexibility to cater to each plant's specific needs and installation requirements. The Walfire Radiant Wall Burner is ideal for applications requiring efficient, safe, and environmentally friendly hydrogen fuel combustion.

NOVALT™ Gas Turbines represent cutting-edge technology in gas turbine power generation, designed for high efficiency and industrial use. Manufactured and tested in Italy, these turbines feature special adaptability to support a wide range of applications. These turbines are capable of operating on natural gas or a mixture of hydrogen and natural gas.

These turbines have the capability to reduce NOx emissions to low levels while maintaining high energy efficiency. They can generate electricity ranging from 5 to 16.9 megawatts.