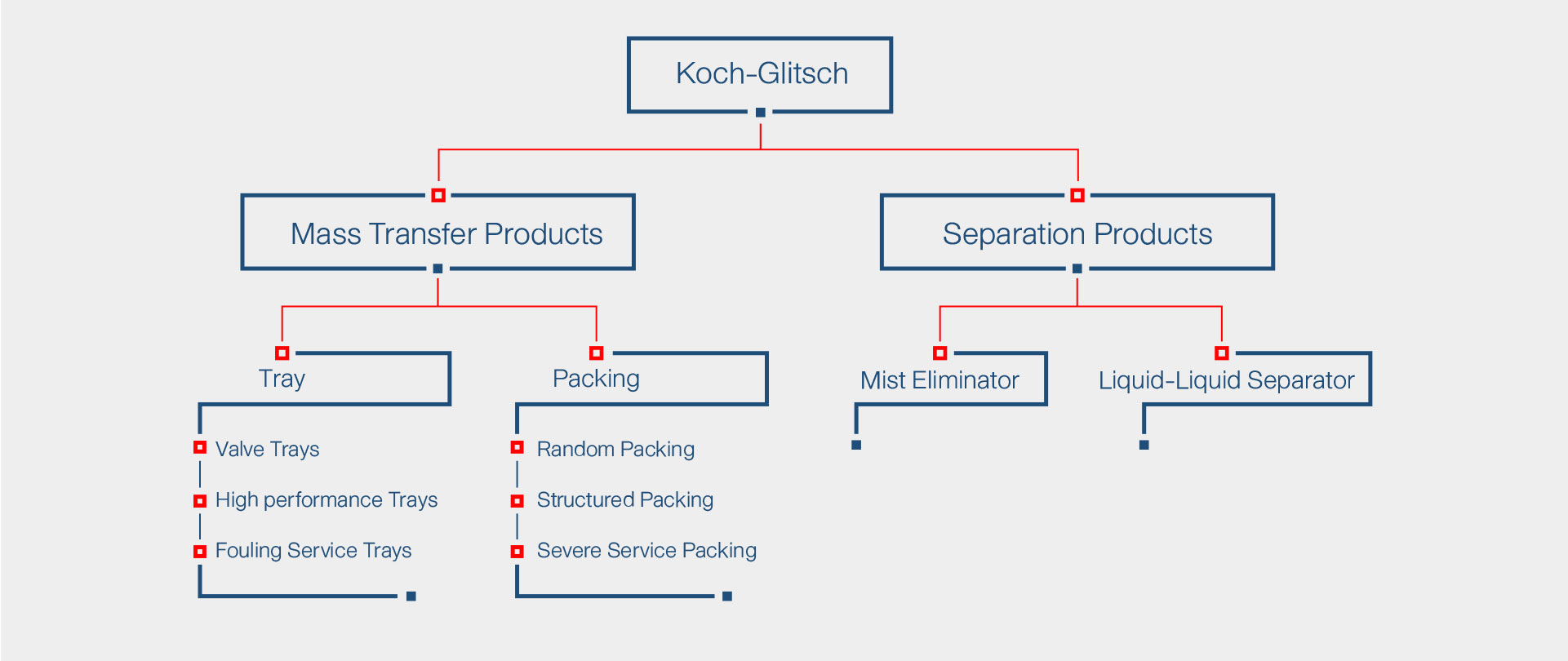

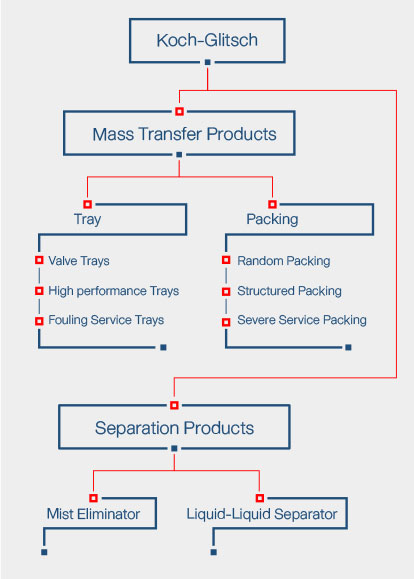

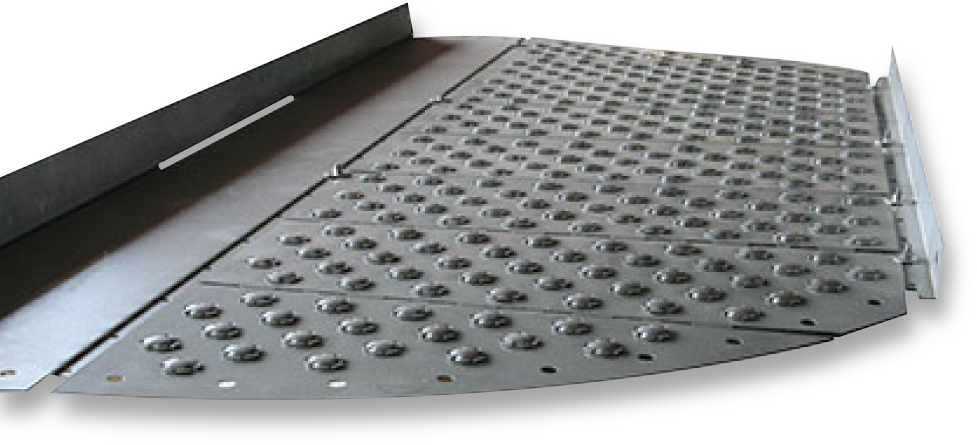

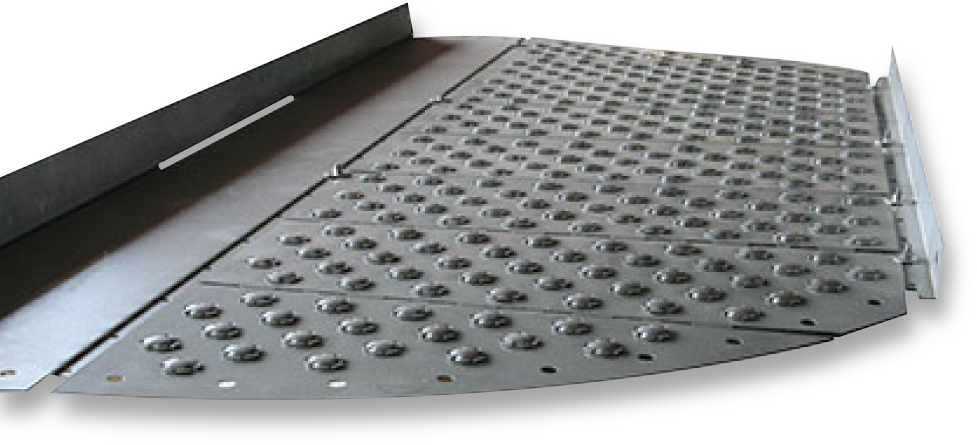

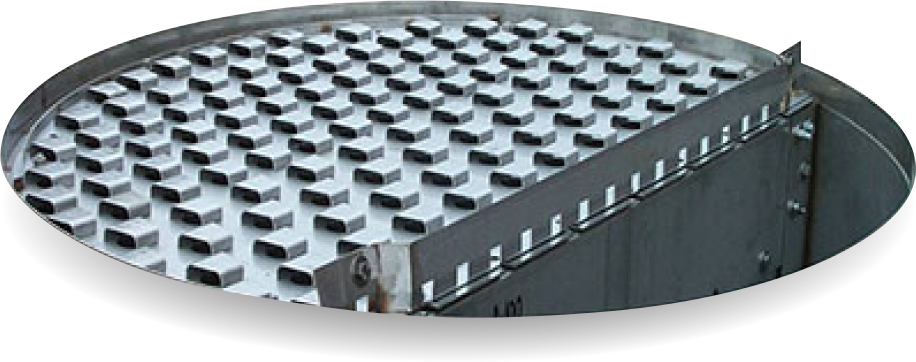

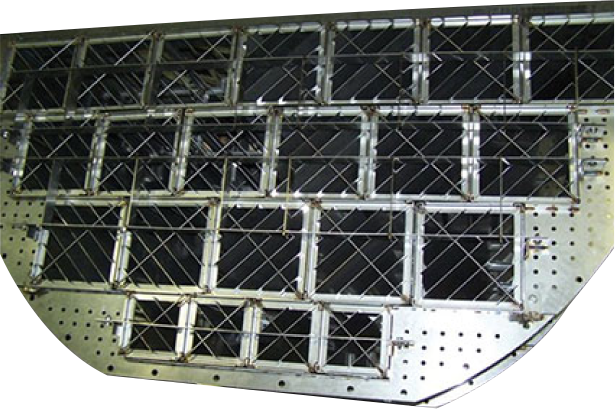

: Tray.

: Trays are separation devices that facilitate good contact between liquid and vapor in a confined space and then provide a zone for disengagement of the liquid and vapor. Mass transfer of vapor-liquid will occur on tray panel.

: Koch-Glitsch provide the industry with higher efficiency, higher capacity, improved plant performance, and increased reliability. Our innovative products yield significant capital and energy savings.

: Refinery, Aromatics, Olefins, Petrochemical.

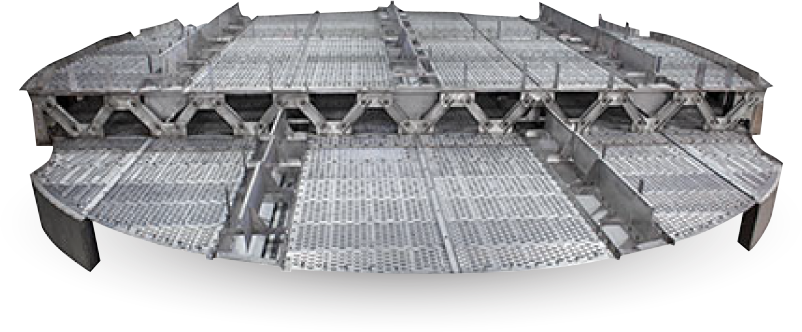

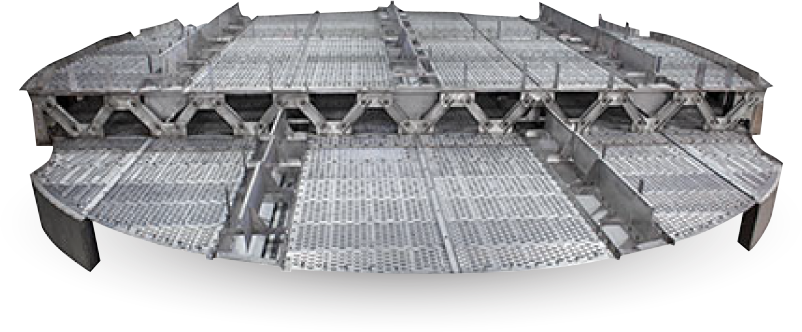

: Tray.

: Trays are separation devices that facilitate good contact between liquid and vapor in a confined space and then provide a zone for disengagement of the liquid and vapor. Mass transfer of vapor-liquid will occur on tray panel.

: Koch-Glitsch develop nrw technology and improve existing correlations to more accurately predict achievable performance.

: Refinery, Aromatics, Olefins, Petrochemical.

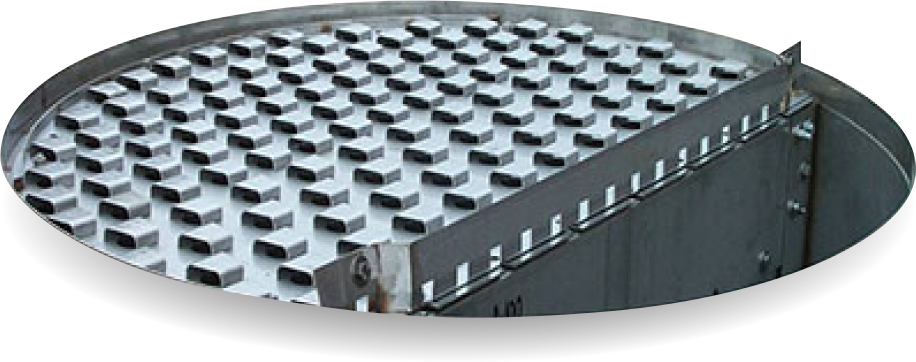

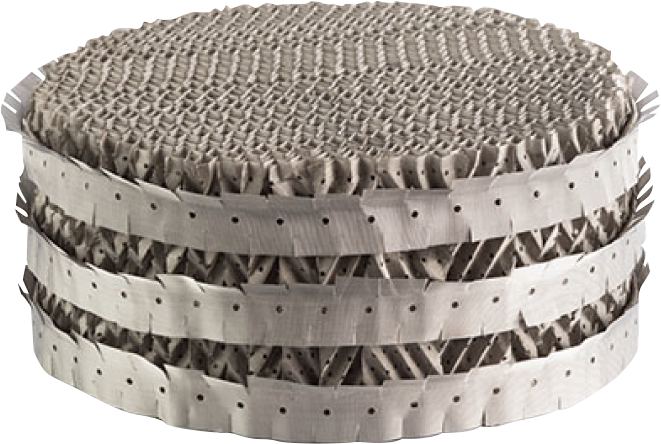

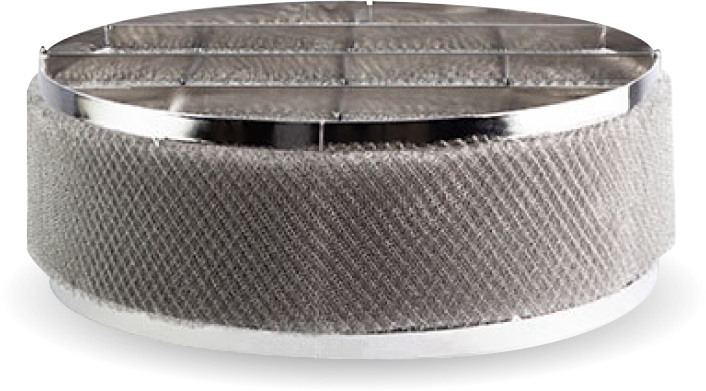

: Mist Eliminator

: Mist Eliminator is separation device that remove droplet from gas steam.

: A mist elimination system featuring process tower internals from Koch-Glitsch can help

: Refinery, Aromatics, Olefins, Petrochemical.

: Refinery, Aromatics, Olefins, Petrochemical.

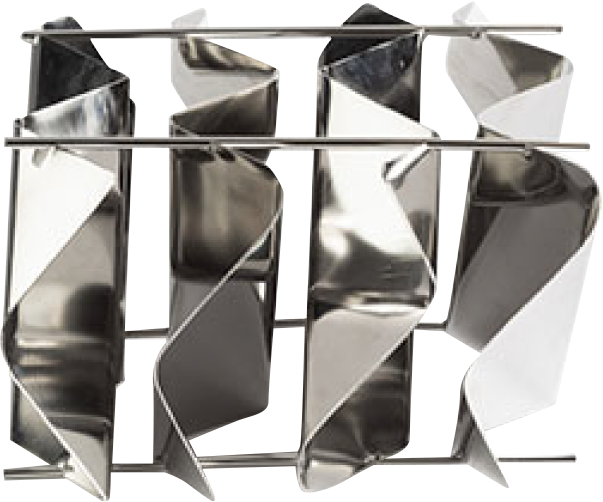

: Liquid-Liquid Separator

: Liquid-Liquid Separator is separation device that separate immiscible liquids. Droplet dispersions require extensive settling when they must travel long distances to the coalescing unit. Liquid-liquid coalescer units uses enhanced gravity settling to allow increased throughput capacity and improve product purity.

: Enhance gravity settling to allow increased throughput capacity and improve product purity.

: Petrochemical.

: Petrochemical.