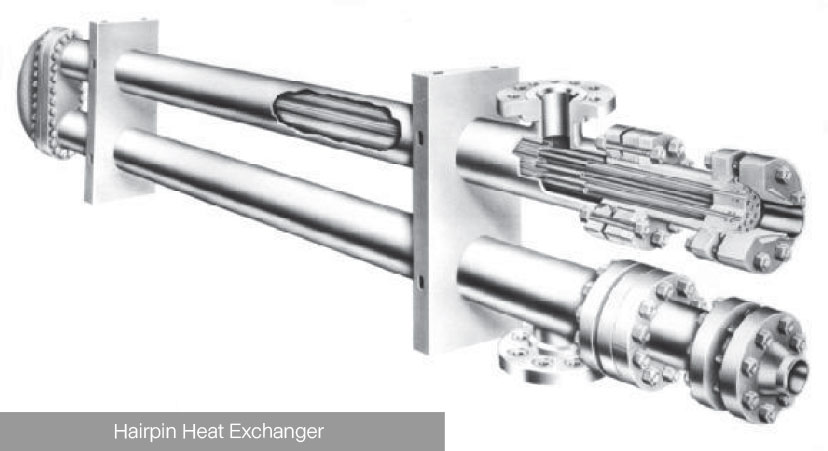

Hairpin is one of the heat exchanger types with separated terminal tube side and shell side closures altogether with large U-Bend. The design of hairpin provide the true counter-current flow which brings many performance advantages and allows for handling with wide range of process conditions.

For Cyclic or Shock Service, Eliminates need for expansion joints

Address Extreme Terminal Temperature Differential

Address Temperature Cross

Allows for High Pressure Applications

Refinery, Olefins, Aromatics, Phenol, Glycol

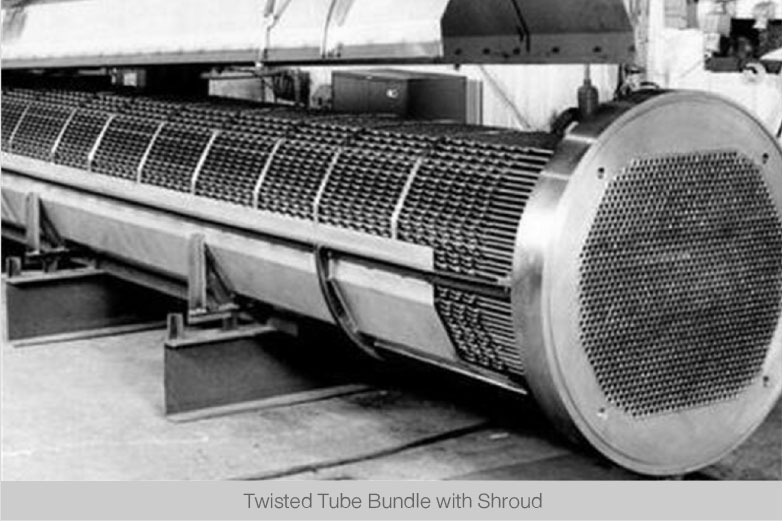

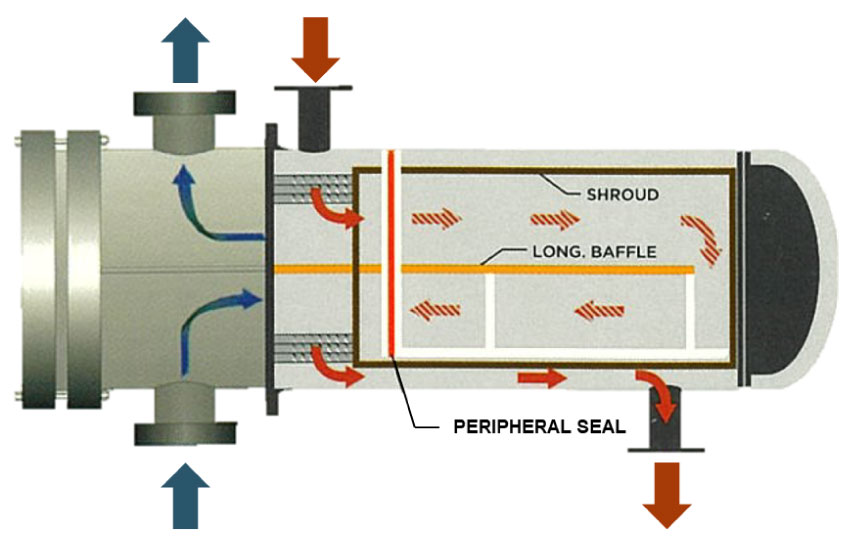

The twisted tube design eliminates baffles and damaging tube vibration. With uniquely shaped tubes, the bundle arrangement provide adjacent support as fluid swirls freely alongside. Gaps between the tubes make it easier to clean on the shell side. The twisted tube bundle can be fitted in the existing conventional shell design without requiring shell modification.

Increased Heat Transfer

Potential Fouling Mitigation

Reduced Pressure Drops

Eliminate Flow Induced Vibration

Bundle Center Cleanability

Reduced Leaking Risk

Refinery, Olefins, Aromatics

Example of fluid flow inside twisted tube heat exchanger